The Future of Street Sweeper Trucks: Innovations via 3D Printing

The landscape of urban cleaning is continually evolving, driven largely by the advancements in technology. One area that has seen remarkable changes is the production of street sweeper trucks. As cities grow and the need for clean, safe public spaces increases, the demand for efficient and effective street cleaning solutions also rises. Enter 3D printing technology — a game-changer in the manufacturing of street sweeper trucks.

Understanding Street Sweeper Trucks

Street sweeper trucks are specialized vehicles designed for cleaning streets, sidewalks, and parking lots. These trucks feature a unique combination of sweeping mechanisms, water tanks, and sometimes even vacuum systems to remove debris, dust, and litter from urban environments. Their importance in maintaining the aesthetic and sanitary conditions of metropolitan areas cannot be overstated.

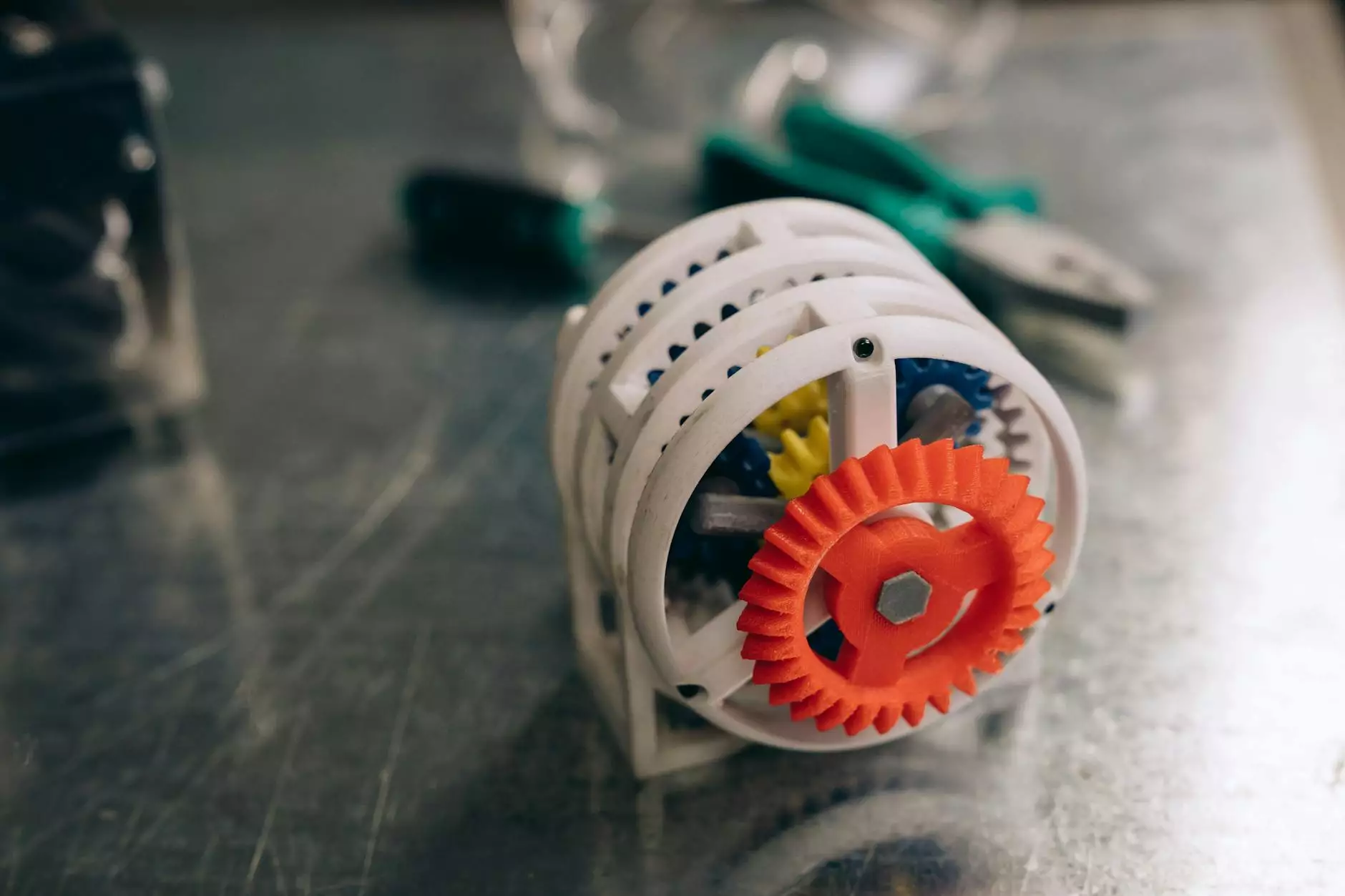

The Role of 3D Printing in Manufacturing

3D printing, or additive manufacturing, has revolutionized various industries, allowing for the creation of intricate parts and products with previously unimaginable efficiency and cost-effectiveness. In the context of street sweeper trucks, 3D printing offers several benefits, particularly in terms of design flexibility and rapid prototyping.

The Advantages of 3D Printing for Street Sweeper Trucks

- Design Flexibility: 3D printing allows for complex designs that can be tailored to specific needs. This means components of street sweeper trucks can be optimized for performance and efficiency.

- Reduced Production Costs: Traditional manufacturing methods can be expensive, especially for custom parts. 3D printing significantly cuts down costs and allows for economical production in smaller batches.

- Faster Prototyping: Engineers can create prototypes quickly, allowing for rapid testing and iteration on designs before full-scale production.

- Lightweight Components: 3D printed parts can be manufactured using lightweight materials, enhancing fuel efficiency in street sweeper trucks.

- Sustainability: 3D printing can reduce waste material compared to traditional subtractive manufacturing methods, making it a more environmentally friendly option.

Key Components of Street Sweeper Trucks Perfected by 3D Printing

Several components of street sweeper trucks lend themselves to the benefits of 3D printing:

Brush Systems

The brush systems are crucial for any street sweeper truck. The design and material used can greatly affect performance. With 3D printing, manufacturers can create customized brush designs that optimize debris pickup and are tailored to specific street conditions.

Pneumatic Systems

The pneumatic systems in street sweeper trucks serve to control the brushes and sweeping mechanics. 3D printing allows for the creation of lightweight yet durable components that enhance the efficiency of these systems.

Chassis and Frame Components

Utilizing 3D printing for chassis and frame components allows for lightweight constructions, which can improve fuel efficiency and ease of handling. The durability of 3D printed materials means that these components can withstand the harsh conditions of street cleaning operations.

Case Studies of 3D Printing in Street Sweeper Truck Manufacturing

Many companies are already at the forefront of integrating 3D printing into their production lines for street sweeper trucks. Here are a few notable examples:

Company A: Reducing Lead Times

Company A implemented 3D printing to streamline its production process. By creating critical parts in-house, they reduced lead times from weeks to days, allowing them to respond more quickly to client needs and reduce downtime in operations.

Company B: Enhancing Customization

Company B utilized 3D printing to offer tailored solutions for their street sweeper trucks. They could quickly adapt components based on customer specifications, resulting in increased customer satisfaction and loyalty.

Challenges and Considerations in Adopting 3D Printing

While 3D printing presents numerous advantages, there are also challenges that companies must address:

- Material Limitations: The selection of materials for 3D printing may not always meet the rigorous demands of street sweeping tasks.

- Regulatory Standards: Compliance with safety and environmental regulations can complicate the integration of new manufacturing techniques.

- Initial Investment Costs: The upfront costs of 3D printing equipment can be high, despite long-term savings.

Future Trends in Street Sweeper Trucks and 3D Printing

As technology continues to evolve, the future of street sweeper trucks and 3D printing looks promising. Here are some trends to watch:

Integration of Smart Technologies

More street sweeper trucks are likely to incorporate smart sensors and IoT (Internet of Things) technologies, providing real-time data on performance and maintenance needs. The ability to prototype these smart components rapidly with 3D printing will be crucial.

Advanced Materials

One of the key areas where 3D printing will evolve is in the development of new materials that are stronger, lighter, and more adaptable for use in street sweeper trucks. Innovations such as biodegradable materials could also contribute positively to sustainability efforts.

Collaborative Manufacturing Models

The adoption of collaborative production models where multiple companies utilize shared 3D printing resources could emerge, fostering innovation and reducing costs across the industry.

Conclusion

In conclusion, the integration of street sweeper trucks into the realm of 3D printing technology represents a significant leap forward in urban cleanliness and efficiency. The advantages of customizability, cost reduction, and sustainability make 3D printing an invaluable asset in the manufacturing of these essential vehicles. As we look to the future, the collision of traditional industries with cutting-edge technology promises to redefine how cities maintain their streets, ensuring they remain clean and welcoming for all inhabitants.

For businesses looking to delve into this transformative approach, the journey begins with the right partners, like ceksansweepers.com, who can guide them through the complexity of 3D printing and its applications in street sweeper truck manufacturing.